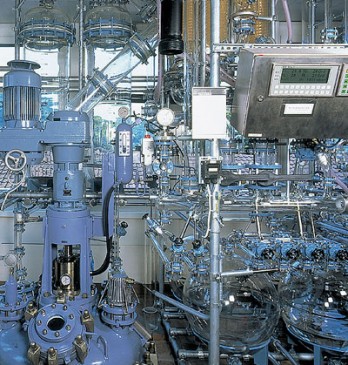

Glass Distillation Superstructure

Chemical Process Equipment: Comprehensive Solutions for Chemical and Pharmaceutical Applications

Büchi’s chemical process equipment offers robust and reliable systems for laboratory, pilot-scale, and production environments. With a legacy of Swiss engineering excellence, these systems are designed to meet the most demanding standards for chemical resistance, safety, and operational efficiency.

Applications

Büchi’s glass equipment supports a variety of processes, including:

- Reaction, stirring, and mixing.

- Vacuum distillation, azeotropic separation, and rectification.

- Absorption, extraction, and phase separation.

- Evaporation and crystallisation.

Key Features

- Materials & Construction:

- Corrosion-resistant materials like borosilicate glass, PTFE, and glass-lined steel.

- Smooth, non-porous surfaces for easy cleaning and superior chemical resistance.

- Innovative Design:

- Flexible “büchiflex” glass connection system ensures stress-free, safe, and easy installation.

- Customisable configurations with packed columns, heat exchangers, and phase separators.

- Efficiency & Safety:

- ATEX and CE certifications with compliance to cGMP and FDA standards.

- Transparent components allow real-time process monitoring.

- Scalable Solutions:

- Systems available for lab-scale (5–15 litres), pilot-scale (15–250 litres), and production-scale (up to 10,000 litres).

- Customisation options to suit specific processes, including cryogenic applications and high-temperature operations.

Why Choose Büchi?

Büchi delivers end-to-end solutions, from design and engineering to installation and validation. Their commitment to innovation, quality materials, and advanced technology ensures efficient and safe chemical processing at any scale.